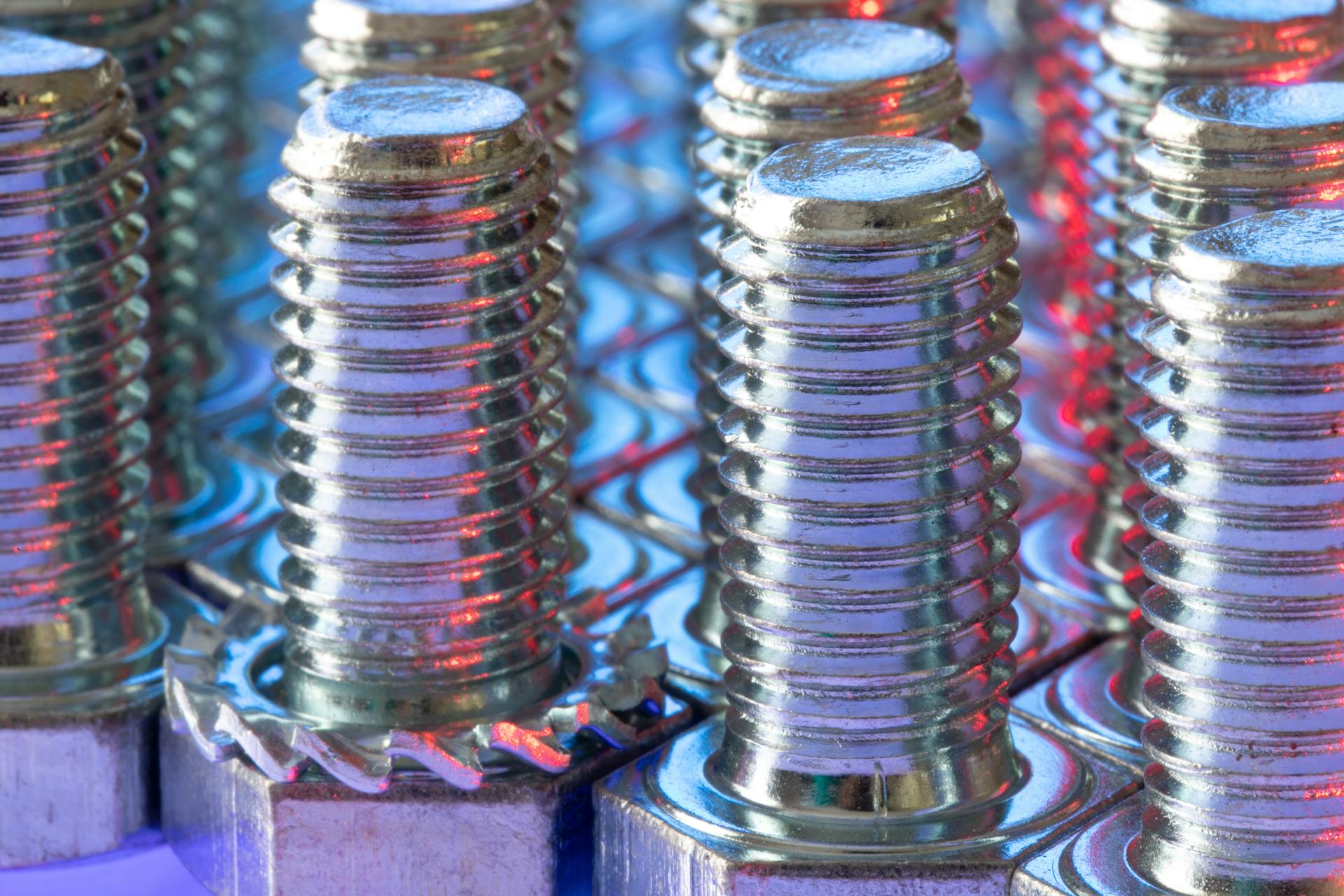

Metal roof screws are a crucial component in securing metal roofs, but choosing the right type can be overwhelming. There are two main types: ridge screws and flat screws.

Ridge screws are specifically designed for metal roof ridges, where two roof planes meet. They have a unique thread pattern that allows for better grip and stability in this critical area.

Flat screws, on the other hand, are used for flat sections of the roof. They have a coarser thread pattern than ridge screws, which provides extra holding power on smooth surfaces.

Proper installation is key to ensuring the longevity of your metal roof.

Proper Placement and Installation

Proper screw placement and installation are crucial for a metal roof's longevity and performance. The number of screws, rake edges, seams, and fasteners needed depends on the design of your metal roof.

Loose or deteriorated screws and fasteners are a common issue with corrugated metal roofing. Many problems can be traced back to improper installation, including loose or deteriorated screws.

Intriguing read: Sealing Ridge Cap on Metal Roof

Using the right type of screw is essential for a sturdy and long-lasting roof installation. Metal self-tapping screws with thin washers are recommended for metal roofing.

Screws should be placed in the flat areas right next to the raised ridges for a tight seal, reducing the risk of water seeping in. This is the best practice for ideal screw placement.

The location of screw placement on metal roof panels can impact the overall performance and longevity of the roof. There are three main options for screw placement: ribs, ridges, and flats.

Here's a comparison of the three options:

Placing screws in the ribs of metal panels can help maintain a watertight seal and minimize the risk of leaks. However, this method can be more time-consuming and may require specialized fasteners.

Screws should be spaced evenly, especially near overlaps and edges, to maintain the roof's integrity and water resistance.

Pre-Drilling and Fastening

Pre-drilling can help ensure accurate placement and reduce the risk of under-tightening or over-tightening, especially when attaching metal roofing to a wooden surface.

Proper pre-drilling can also prevent metal sheets from getting damaged, which is especially necessary for thicker metal sheets or when using screws without self-drilling tips.

Using the correct drill bit size and maintaining precision is key to pre-drilling effectively, as it helps avoid compromising the roof's integrity.

Pre-drilling can be beneficial when using self-tapping screws, but it's not always necessary, as many metal roofing screws are self-drilling.

Pre-drilling gone wrong can actually create more opportunities for moisture to penetrate later, so it's essential to get it right.

Pre-drilling can also make it easier to plan out your fastener spacing ahead of time, which is particularly useful when attaching metal roofing to a solid wood substrate.

Choosing the Right Fasteners

Choosing the right fasteners is crucial for a secure and reliable metal roof.

A good starting point is understanding the different types of screws and fasteners available, such as metal-to-wood screws, metal-to-metal screws, sealing tape, and lap screws. These types are designed for specific applications and can help determine the right choice for your project.

When it comes to attaching metal panels to wooden substrates, metal-to-wood screws are the way to go.

Here are some common types of screws and fasteners to consider:

- Metal-to-Wood Screws: for attaching metal panels to wooden substrates

- Metal-to-Metal Screws: for connecting metal panels to other metal components

- Sealing Tape: for creating a watertight seal between metal panels

- Lap Screws: for securing overlapping metal panels

Types of Fasteners

Choosing the right fasteners for your project can be overwhelming, but understanding the different types available can make all the difference.

Metal-to-Wood Screws are designed for attaching metal panels to wooden substrates, such as plywood or framing. This type of screw is essential for securing metal roofing to a wooden base.

Metal-to-Metal Screws connect metal panels to other metal components, like purlins or other metal panels. They provide a strong and durable connection.

Sealing Tape is often used to create a watertight seal between metal panels, preventing moisture infiltration. This is a crucial step in ensuring the integrity of your metal roofing system.

Lap Screws secure overlapping metal panels, ensuring a tight connection between panels. They provide extra security and stability to your metal roofing.

Here are some common types of fasteners for metal roofing:

Length Importance

A screw that's too short may not anchor the metal sheet securely, while one that's too long could pose other structural concerns.

The right length of a screw is crucial for a lasting grip, ensuring your roof remains steadfast, come rain or shine.

A screw that's too short can compromise the entire installation, so it's essential to get it right.

Ensuring the right length of a screw ensures that your roof remains securely fastened, protecting it from harsh weather conditions.

Common Fastening Issues

Over-tightening or under-tightening can both result in leak points, making it a common fastening issue in metal roof installations.

Overtightening can cause the washer to break or the screw to lose its grip, leading to potential leaks. This can happen when you try to sink the screw as far down as it will possibly go, overcompressing the washer and creating too much stress.

A screw that's underdriven doesn't create a proper seal for the washer, and that can result in leaks, too. If you can still spin the washer after you've put in your screw, that's a good indication that the screw is under tightened.

Using a screw gun specifically designed for metal roofing fasteners can help avoid these issues, as it's set to exact speed and torque specifications for specific metal roofing gasket fasteners. This is a crucial step in ensuring a secure and reliable metal roof.

To avoid over-tightening and under-tightening, it's essential to adhere to the manufacturer's recommendations for appropriate torque levels. This will help you achieve the perfect balance between a secure screw and a leak-free roof.

Consider reading: Secure Decorations

Roofing Tips and Considerations

Securing metal roofing involves more than just screwing in fasteners. Using the right type of screw is crucial for a sturdy and long-lasting roof installation.

Proper pre-drilling of holes for precision is essential to avoid damaging the metal roofing.

Tightening screws without over-torquing is also vital to prevent screws from working themselves loose.

Metal roofing is an excellent choice for residential and commercial projects, especially in areas prone to hurricanes or other natural disasters.

Metal roofs are incredibly durable and require very little maintenance, making them a great choice for many homeowners.

A well-installed metal roof can be insulated for energy efficiency, outperforming other types of roofing systems.

The biggest source of potential problems in metal roofing comes down to the installation, not the metal itself.

Proper handling of screws and fasteners is crucial to prevent moisture intrusion at lap screws, metal-to-wood screws, and metal-to-metal screws.

Metal roofing can require thousands of screws, fastener sites, and seams, each of which is a potential source of moisture intrusion if not handled correctly.

Avoiding Mistakes

Metal roof screws in ridge or flat applications require careful consideration to avoid common mistakes.

Proper installation is crucial for optimal performance, including accurate screw fastening.

A secure and reliable metal roof starts with correct screw placement, typically 6-8 inches apart.

Avoid over-tightening, which can lead to damaged roofing material and compromised structural integrity.

Choosing an Expert Contractor

Choosing an Expert Contractor is key to avoiding mistakes in your roofing project. A qualified contractor will understand the nuances of screw fastening and placement.

Experience is crucial when it comes to installing a metal roof. A contractor with experience will know how to get the job done right.

A knowledgeable contractor will ensure a durable, long-lasting, and efficient roofing system. This is especially important for metal roofs, which require proper installation to function properly.

How Many Roofers?

As you plan your roofing project, one of the most important things to consider is the number of roofers you'll need. A common guideline is to have one roofer for every 1,000 to 1,500 square feet of roofing area.

The type of metal roofing you choose can also impact the number of roofers you'll need. Standing seam roofs, for example, often require a more complex installation process, which may necessitate a larger team of roofers.

Explore further: Do You Need Gutters on a Metal Roof

The complexity of the roof design can also affect the number of roofers required. A roof with many valleys, hips, or skylights may need more roofers to ensure a proper installation.

In general, it's better to err on the side of caution and have a few extra roofers on hand, just in case. This will help ensure that the job is completed efficiently and to a high standard.

Here's a rough estimate of the number of roofers you may need for different types of metal roofing:

Keep in mind that this is just a rough estimate, and the actual number of roofers you'll need may vary depending on the specific project requirements.

Sources

- https://statewideroofingspecialist.com/blog/guidelines-for-proper-screw-fastening-and-placement-on-metal-roofs/

- https://rmcroofingnm.com/how-many-screws-do-i-need-for-metal-roofing/

- https://skywalkerroofingnc.com/blog/metal-roofing-installation-101-tips-guidelines-for-proper-screw-fastening

- https://www.metalroofingsource.com/install-metal-roofing-fasteners/

- https://www.hansenpolebuildings.com/2016/05/steel-roofing-screw-flats-high-ribs/

Featured Images: pexels.com